EasyCut PC Based CNC Motion Control

&

EasyCut V2 Software

EasyCut PC Base CNC motion controller is for stepper motor or AC servo with cheap price.

Use several MCU to handling different data.Two MCU get and send commands alternately at the same time. So it can get high effect, more smoothly and more stabilize.

Look Ahead Control can make the motion smooth and fast.

Suitable for router/engraving/plasma/laser machine.

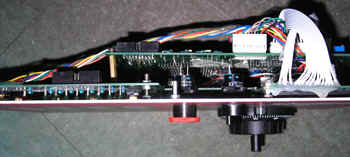

3 axis/4axis MC4 EasyCut Motion Control

MC4 with case

MC4 without case

4 axis EasyCut MC4 Motion Control for Stepper Motor,DC Servo Motor and AC Servo Motor. There are four wiring selection : CW, CCW, Step, Pulse + Code (+ Dir or - Dir).

Promote price is US$998 only. (include EasyCut V2 control software)

EasyCut Probe scanner is US$280 only.

![]()

Stand-alone motion control coming soon!

No computer required

Communicate by USB Disk

3D Probe Scanning

Automatic less the probe diameter after scanning.

Automate Speed Control

Automate slow down the speed when the corner is equal or less than 90 degree. That can avoid to crashing the machine.

Change Feed Rate

Don't need to pause the machine. You can change the cutting speed (10%-300%)while the machine is running.

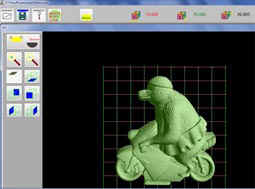

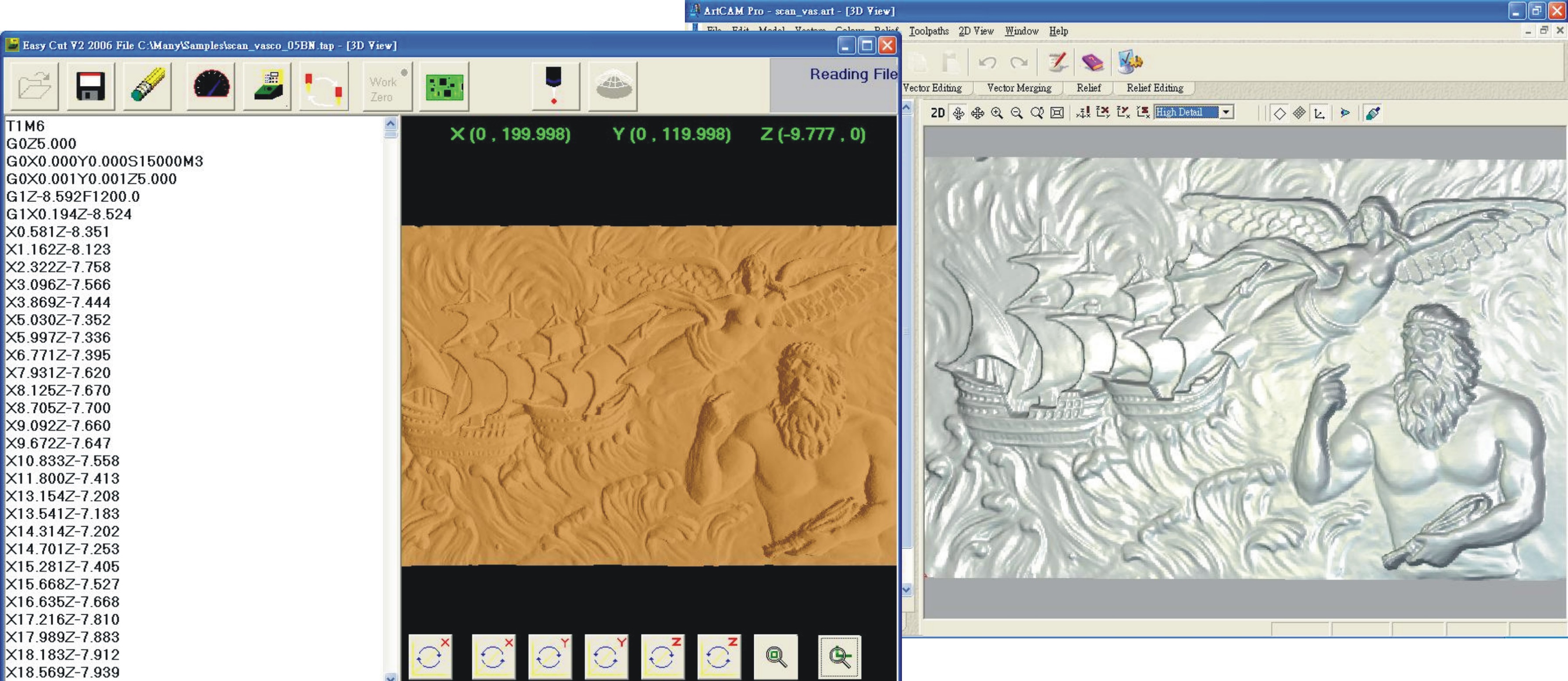

3D Toolpath Simulation

Display the actually 3D solid mold before machining.That can let you know the machining result.

Automatic Tool Measure and Support Tool Changer

Even if without ATC system, just change the tool by hand, it will measure the tool and continue the job automatically.

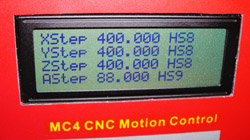

Easy to change the Chips Setting

Easy to change the XYZA Chips setting in MC4 control panel and EasyCut software.

EasyCut MC4 Motion Control Specification

3 axis/4 axis stepper/AC servo PC base CNC control |

|

COM port communicate (56k) |

|

4 x 20 LCD position display |

|

Easy to use JOG and Hand Wheel to set the position |

|

Look Ahead Control can make the machining surface very smooth |

|

The motion will not be affected by the revolution of Windows |

|

Support ISO standard G Code file (S, F, G0, G1, G2, G3, G21, M2, M3, M5, M6, M30) |

|

Unlimited program size |

|

Ability to transfer DXF and PLT file to GM code |

|

Advance read 30 pcs commands |

|

4 axes simultaneous |

|

Pulse output up to 56k/sec |

|

Each axis output frequency max range is +2,147,683,648 |

|

Automatically control the speed at the corner |

|

Automatically control the speed in the straight line |

|

Automate Tool Measure |

|

Automatically Save/Load Work Zero |

|

Automatically reduce the Probe diameter after scanning |

|

Spindle On/Off is controlled by the program. Also can turn on the spindle for JOG moving. |

|

Change cutting speed from 10% to 300% while the machine is running |

|

Support ATC (Auto Tool Changer) |

|

Possible to select the start position after press Stop |

|

3D Toolpath simulation |

|

Special for point machining, it can run smoothly even each distance less than 0.05mm |

|

Limit switch on XYZA axis |

|

Including the software to control the machine |

|

No external PLC hardware |

|

No Visual Basic, Visual C, Borland C++ necessary |

|

Runs under Windows 2000/XP/Vista |

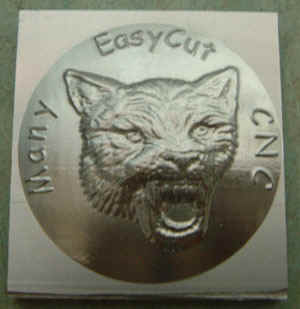

EasyCut 3D Probe Scanner Control System

Less probe diameter after scanning automatically.

Graphical icon easy to use.

Don't need to create the complex drawing, save time and save money.

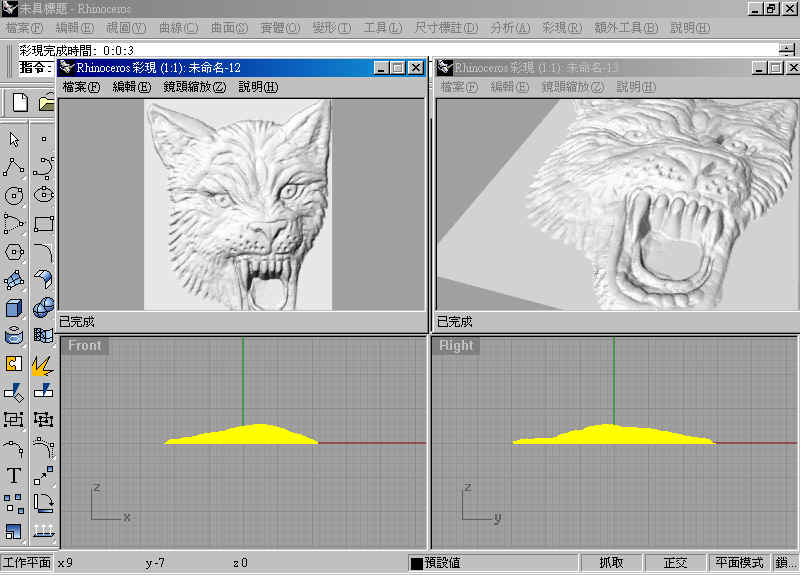

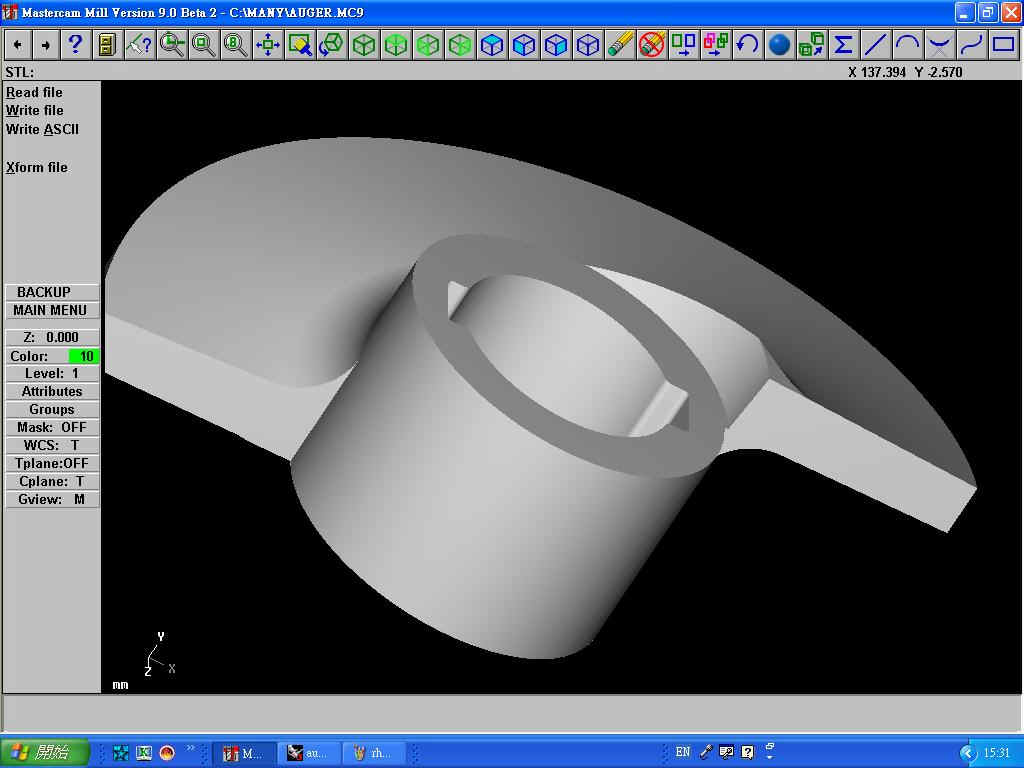

Ability export to 3D DXF file to your CAD/CAM system for any editing (such as ArtCam Pro, CopyCad, PowerMill, RhinoCam, VisualMill, madCad, Type3...)

Easily to create the rough machining and finish machining toolpath program in CAM software.

3D part display while it is scanning.

Full 3D solid simulation of your model will display after ascnning.

![]()

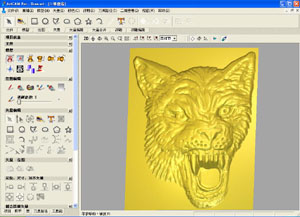

Modify scan file (DXF) and create toolpath file in ArtCamPro

![]()

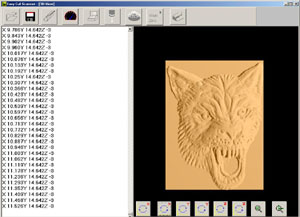

Scan and Scale Machining

Easy create toolpath file in RhinoCam, Vcarve, MasterCam etc CAM software

Optional Motor Control

| USA Gecko Micro Stepper Drive for Stepper Motors (Wiring Diagrams) | |

| Japan Sanyo Denki AC servo control for Sanyo Denki AC servo motor |

Sanyo Servo Motor Control

Computer Requirements

IBM/Intel/Pentium/AMD/Acer Desktop computer or laptop |

|

Windows 2000/XP/Vista |

|

8 x CD ROM or above |

|

COM Port or USB to RS232 |

![]()